Introduction of UNS N08825(Incoloy 825)

Tech Center 2025-09-05 233

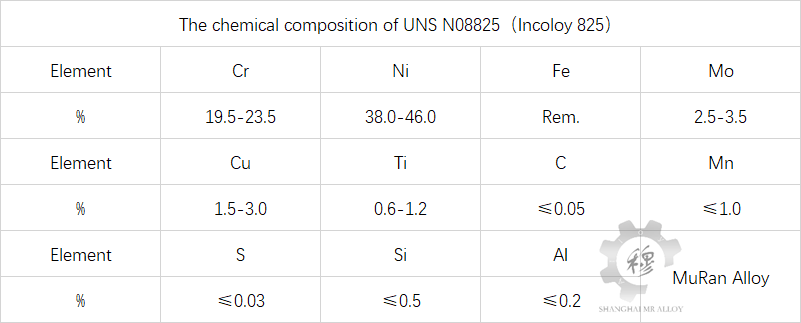

Incoloy 825 alloy is a nickel-iron-chromium alloy with added molybdenum, copper and titanium. Designed to offer excellent resistance to many corrosive environments. The nickel content is sufficient to resist chloride ion stress corrosion cracking. The combination of nickel with molybdenum and copper also provides excellent resistance to reducing environments, such as those containing sulfuric acid and phosphoric acid. Molybdenum also helps resist pitting and crevice corrosion. The chromium content of this alloy makes it resistant to various oxidizing substances such as nitric acid, nitrates and oxide salts. The addition of titanium, after appropriate heat treatment, can stabilize the alloy and prevent sensitization to intergranular corrosion.

Metallographic structure of Incoloy825

Incoloy825 alloy features a stable face-centered cubic structure. Chemical composition and appropriate heat treatment ensure that corrosion resistance is not weakened by sensitization.

Corrosion resistance of Incoloy825

Incoloy825 is a general-purpose engineering alloy that exhibits resistance to acid and alkali metal corrosion in both oxidizing and reducing environments.

The high nickel content endows the alloy with effective resistance to stress corrosion cracking.

It has excellent corrosion resistance in various media, such as sulfuric acid, phosphoric acid, nitric acid and organic acids, as well as alkali metals like sodium hydroxide, potassium hydroxide and hydrochloric acid solutions.

The superior comprehensive performance of Incoloy825 is reflected in the nuclear combustion dissolver with diverse corrosive media, such as sulfuric acid, nitric acid and sodium hydroxide, which are all processed in the same equipment.

Application scope of Incoloy825

Incoloy825 is widely used in various industrial fields where the operating temperature does not exceed 550℃. Typical applications include:

Heating tubes, containers, baskets and chains used in sulfuric acid pickling plants.

Seawater cooling heat exchangers, Marine product pipeline systems, pipelines for acidic gas environments.

Heat exchangers, evaporators, washing machines, impregnation tubes, etc. in phosphoric acid production.

Air heat exchanger in petroleum refining

Food Engineering

Chemical process

Flame-retardant alloys for high-pressure oxygen applications.

The density of this alloy is ρ=8.14g/cm³.