Introduction of UNS N08811(Incoloy800HT)

Tech Center 2025-09-03 255

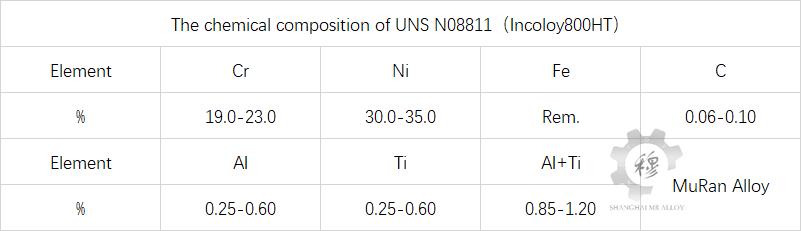

Incoloy 800HT is a fully austenitic low-carbon nickel-iron-chromium alloy of the same series as Incoloy800. The cobalt content in this alloy can be strictly controlled below 0.01%. The Incoloy800HT can resist corrosion from many corrosive media. Its relatively high nickel content endows it with excellent resistance to stress corrosion cracking under water-based corrosive conditions. The high chromium content endows it with better resistance to pitting and crevice corrosion cracking. This alloy has excellent resistance to nitric acid and organic acid corrosion, but its corrosion resistance in sulfuric acid and hydrochloric acid is limited. Except for the possibility of pitting corrosion in halides, it has excellent corrosion resistance in both oxidizing and non-oxidizing salts. It also has excellent corrosion resistance in water, steam, and mixtures of steam, air, and carbon dioxide.

The Incoloy 800HT has the following features:

1.It has excellent creep fracture resistance when the temperature is above 700℃. However, for materials that frequently come into contact with temperatures below 700℃ during service or are partially and permanently exposed to temperatures below 700℃, it is recommended to use Incoloy800H.

- Excellent resistance to corrosion in reducing, oxidizing and nitriding atmospheres, as well as in atmospheres where reducing and oxidizing alternate.

- It has excellent metallographic stability when used for a long time at high temperatures.

Incoloy800H and Incoloy800HT are mostly used in:

- Various components in steam and hydrocarbon reforming hydrogen production, such as transmission pipelines, catalytic converter pipes (for low-pressure processes), and cooling system pipelines;

- Pipeline systems used in the production or cracking processes of various hydrocarbons and chlorinated hydrocarbons;

- Various components in coal-fired power plants such as heat exchangers, pipeline systems, etc.

Application fields of Incoloy 800HT

Nitric acid condenser – resistant to nitric acid corrosion

Steam heating tube – Excellent mechanical properties

Heating element tube – Excellent mechanical properties

For applications in environments up to 500℃, the alloy is supplied in the annealed state.

The density of this alloy is ρ=7.94g/cm³.