Introduction of UNS N08810(Incoloy800H)

Tech Center 2025-09-02 245

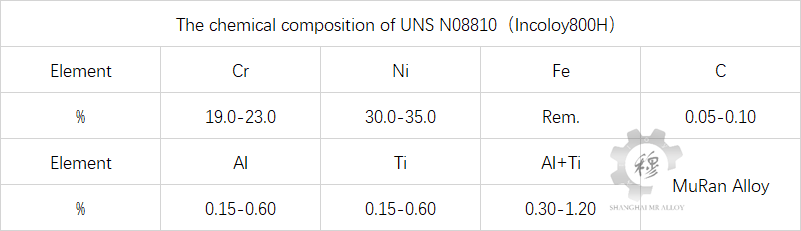

Nickel-iron-chromium alloy, compared with Incoloy 800, has the same matrix composition but significantly higher creep strength. The higher strength stems from the strict control of the contents of C, AI and Ti, along with the combined effect of heat treatment. Used in petrochemical processes, heater and reheater pipeline systems in power plants, industrial circuits, and heat treatment equipment.

Standard product forms: pipes, plates, strips, round bars, flat bars, forgings, wires, and special-shaped materials.

Like Incoloy800 alloy, it is also an austenitic solid solution strengthening alloy with a face-centered cubic lattice structure. Titanium carbide and chromium carbide usually occur in the microstructure.

1.The Incoloy 800H has the following most distinctive features

Due to the limitation of (Ti+AI) content (up to 0.7%), it has excellent creep fracture resistance at temperatures above 600℃ and does not reduce plasticity even after long-term service at 700℃W.

- Excellent resistance to corrosion in reducing, oxidizing and nitriding atmospheres, as well as in atmospheres where reducing and oxidizing alternate. 3. It has excellent metallographic stability when used for a long time at high temperatures.

Corrosion resistance

Incoloy 800H has the same nickel, chromium and iron content as Incoloy 800 and usually shows similar corrosion resistance. Due to its high content, this series of alloys all have excellent oxidation resistance.

Compared with 800,800H and 800HT can be applied at higher temperatures and have excellent strength. At high temperatures, they can resist carbonization, nitriding and oxygen. Additionally, the most outstanding performance of 800H and 800HT is their resistance to hydrogen embrittlement cracking.

Incoloy800H and Incoloy800HT are mostly used in:

- Various components in steam and hydrocarbon reforming hydrogen production, such as transmission pipelines, catalytic converter pipes (for low-pressure processes), and cooling system pipelines;

- Pipeline systems used in the production or cracking processes of various hydrocarbons and chlorinated hydrocarbons;

- Various components in coal-fired power plants such as heat exchangers, pipeline systems, etc.

The density of this alloy is ρ=7.94g/cm³.