The influence of heat treatment process on the microstructure and hardness of Haynes747 superalloy

Tech Center 2025-08-09 158

Haynes747 is a Fe-Ni-Cr-al age-hardened deformable superalloy. Due to its excellent high-temperature strength, high-temperature oxidation resistance, corrosion resistance and structural stability, as well as its ease of forming and welding, its maximum service temperature is 1300℃. Haynes747 can be widely used in the manufacturing of high-temperature oxidation-resistant parts for aerospace, nuclear power, petrochemical, metallurgy and other fields. Currently, there is relatively little research on Haynes747 superalloy at home and abroad, mainly focusing on the manufacturing, microstructure and performance of seamless tubes. There are currently no relevant reports on the influence of heat treatment temperature and holding time on the microstructure and hardness of Haynes747 alloy. In this paper, Haynes747 superalloy cold-rolled seamless tubes were manufactured using industrial production equipment, and the influence of heat treatment systems on their microstructure and hardness was studied. It is hoped that this experiment can provide a theoretical basis for formulating industrial heat treatment specifications for this alloy.

Preparation of test materials

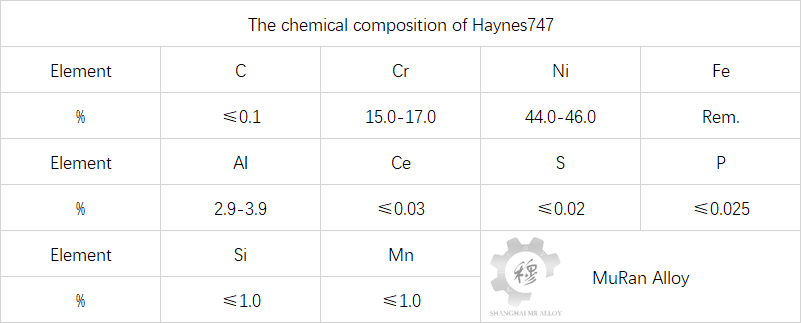

Haynes747 alloy is smelted and cast in a 12t vacuum induction furnace with 360mm×280mm alloy ingots. Then, it is smelted by a 430mm electroslag remelting process, rapidly forged, and opened into 200mm octagonal square billets. Subsequently, 70mm round tube billets are radially forged, followed by processes such as skinning, cutting, and drilling center holes. Finally, the wastewater pipe with a diameter of 70mm×7mm was hot-stamped. The specific chemical composition is shown in Table 1. The original gh2747 pipe was cold-rolled twice to the finished pipe with a diameter of 25mm×3mm, and then the Haynes747 was degreased. The chemical composition is shown in the table below.

Experimental method

The longitudinal metallographic specimens under the above-mentioned different heat treatment conditions were ground and polished. Then, they were electrolyzed with a mixed solution of 3L oxalic acid and 100ml concentrated hydrochloric acid. They were observed and photographed under a Zeiss axiovert 40mat metallographic microscope. Five different longitudinal metallographic structure fields were randomly selected under each heat treatment condition. The grain size was measured by the dividing point method in GB/T 6394-2017 “Method for Determination of Average Grain Size of Metals”, and the average grain size of five different fields of view was calculated. The hardness specimens under each heat treatment condition shall be transversely ground and polished, and then the Vickers hardness of HV30 shall be tested on a 570had digital Brinell hardness tester in accordance with the requirements of GB/T 43401-2009 “Metallic materials – Vickers Hardness Test – Part 1: Test methods”

Test Conclusion

Based on the microscopic observation results and mathematical formula calculations, the following conclusions are drawn:

(1) When the heat treatment temperature is 1000℃, as the heat treatment temperature increases, the grains of Haynes747 alloy become fine and uniform, and the grains gradually grow larger. When the heat treatment temperature is 1000 to 1050℃, the grains of Haynes747 alloy are more uniform. When the temperature exceeds 1050℃, individual grains grow significantly

(2) Under different holding times, the average grain size of Haynes747 alloy shows the same trend as the heat treatment temperature. Within the temperature range of 1000 to 1075℃, the grains gradually grow as the temperature increases. The grain growth of Haynes747 alloy is slow. When the temperature exceeds 1075℃, The apparent activation energy of grain boundary migration is 2349kj/mol

(3) At different heat treatment temperatures, the average grain size of Haynes747 alloy increased with the extension of holding time after the holding time exceeded 20 minutes, and the grain growth rate slowed down the change of average grain size with holding time. The kinetic time index of Haynes747 alloy at 1000-1075℃η is approximately 039, which conforms to Baker’s formula. When the temperature exceeds 1075℃, the temperature drops

(4) Under different heat treatment systems, the Vickers hardness and average grain size of Haynes747 alloy conform to the Hall-Petch equation

It is hoped that this experiment by MuRan can bring some inspiration to all technical researchers!