Introduction of UNS N07718(Inconel 718)

Tech Center 2025-08-18 170

Introduction of UNS N07718(Inconel 718)

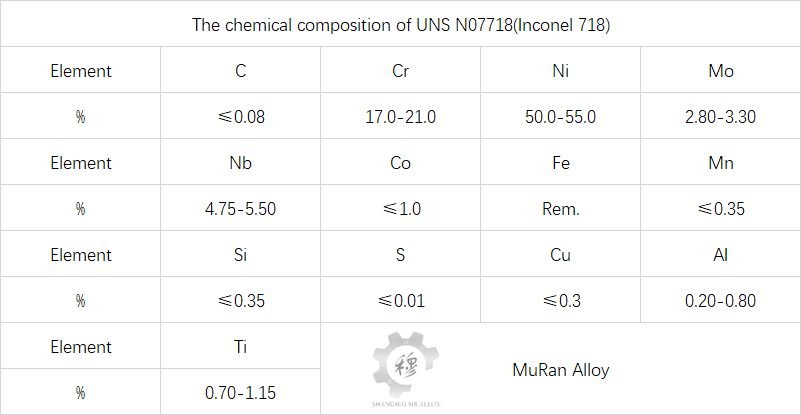

UNS N07718(Inconel 718) superalloy is a Ni-Cr-Fe-based deformable alloy developed by the United States in 1959 (corresponding to the Chinese grade GH4169). In 1962, International Nickel Corporation of the United States applied for patent protection for it. Due to its excellent high-temperature microstructure stability, oxidation and corrosion resistance, and weldability, as well as its outstanding fatigue and creep resistance, it has become one of the most widely used superalloys at present (accounting for 40% to 50% of the world’s total superalloy production). As a structural material for aero engines, UNS N07718(Inconel 718) alloy is subject to the combined effects of high temperature, stress, and corrosion during service. Its working state is affected by the interaction of fatigue and creep, and the service life is closely related to the evolution of the alloy microstructure under service conditions. Especially when in long-term service above 650 ℃, the main strengthening phase γ “phase in the alloy will roughen or transform into δ phase.

UNS N07718(Inconel 718) Hot working

(1) The recrystallization behavior of UNS N07718(Inconel 718) alloy during high-temperature deformation is controlled by continuous recrystallization and discontinuous recrystallization mechanisms. Abnormal growth of recrystallized grains will occur in large-sized forgings after deformation due to slow cooling. Appropriately reducing the recrystallization degree before final forging to precipitate sufficient needle-like δ phase can effectively inhibit grain growth by taking advantage of the grain boundary ligation effect of δ phase. Rapid cooling can generate residual stresses of 400 to 500 MPa in forgings. Reasonable control of these stresses can improve the service performance of the components.

(2) The solidification microstructure orientation of the UNS N07718(Inconel 718) alloy formed by selective laser melting is obvious, and thus it shows anisotropy of mechanical properties. High-temperature solution treatment, while eliminating the segregation of the Laves phase, alters the dislocation substructure, grains and texture orientation in the solidified structure, thereby affecting its mechanical behavior.

(3) During the creep process of UNS N07718(Inconel 718) alloy, dislocations show planar sliding characteristics on the matrix, accompanied by the generation of twins. The sliding dislocations will shear the g” and g ‘phases and leave striped displacements within them, while there are no displacement shear characteristics in the alloy matrix. The γ” phase of the D022 structure has a more complex dislocation shearing mechanism than the γ ‘phase, and more experimental verification is still needed.

(4) While retaining the advantages of low cost, forgeability and easy weldability similar to UNS N07718(Inconel 718) alloy, further increasing the service temperature is an important criterion for the design of new deformable nickel-based alloys. For example, the Allvac 718Plus alloy is based on the Inconel 718 alloy. It was developed through composition adjustment and alteration of the strengthening phase structure (its service temperature was increased by 55 ℃). The acquisition of γ”-γ ‘composite precipitation structures with excellent thermal stability under different composition systems provides a new strategy for the development of deformed nickel-based alloys.

(5) For the UNS N07718(Inconel 718) alloy formed by SLM process, more work is needed to characterize and evaluate its solidification substructure configuration and its influence on mechanical behavior, and to study the microstructure evolution characteristics that are different from those of forged alloys during high-temperature service. Based on the special crystal structure of the γ” phase and its composite precipitation morphology with the γ phase, the complex deformation mechanism of the precipitation phase of UNS N07718(Inconel 718) alloy at high temperatures requires further experimental verification.

The above is an introduction to the UNS N07718(Inconel 718) alloy material and process. Our company’s official website (wellalloy.com) updates alloy information on a daily basis. We welcome everyone’s suggestions and exchanges.