Introduction of UNS N07001(Waspaloy)

Tech Center 2025-08-19 201

Overview of UNS N07001(Waspaloy)

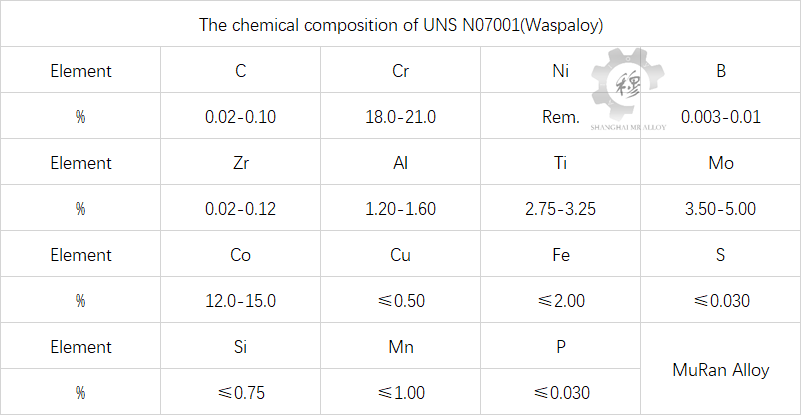

UNS N07001(Waspaloy) alloy is a nickel-based deformable superalloy strengthened by γ ‘phase precipitation. The international similar alloy grade is Waspaloy. This alloy features high yield strength, fatigue crack propagation resistance and corrosion resistance within the temperature range of 760-870℃. Therefore, it is widely used in aerospace, petrochemical and other fields, and is suitable for manufacturing turbine discs, blades, ring-shaped parts, bolt fasteners, etc.

UNS N07001(Waspaloy) alloy is a nickel-based superalloy strengthened by γ ‘phase. Its outstanding feature is the excellent matching of strength and toughness and the ability to resist creep fatigue interaction, thus making it an important material selection for components in aero engines.

Application Overview and Features of UNS N07001(Waspaloy)

Alloys have been used to manufacture turbine discs, blades and sealing rings for aero engines, as well as blades, turbine discs and large bolts for flue gas turbines. This alloy is widely used in the rotating parts of equipment in the fields of aviation, aerospace, petroleum, chemical engineering and power generation abroad, such as compressor blades, turbine discs, valve bodies, annular parts and shafts and other rotating parts.

The alloy exhibits excellent oxidation resistance and corrosion resistance in various atmospheres encountered under jet engines or similar working conditions. The oxidation resistance temperature for continuous operation can reach 1040℃, and for intermittent operation, it can reach 870℃. The alloy also has good resistance to salt spray corrosion, especially in the solution treated state, which is the best. After the bar was treated at 1080℃×4h/AC+ stabilization + aging, the notch endurance tests at 650℃, 750℃ and 815℃ showed that the alloy had no notch sensitivity. After long-term aging at 650°C and 730°C for 3000 hours, no new phase precipitated and the microstructure remained stable.

UNS N07001(Waspaloy) smelting process

The smelting process adopts vacuum induction furnace + vacuum arc (or self-consumed furnace)+ electroslag remelting, or vacuum induction furnace + electroslag remelting + vacuum arc remelting.

The influence of the final forging temperature on UNS N07001(Waspaloy)

(1) Under the same final forging temperature conditions, a lower terminal temperature is not conducive to the occurrence of dynamic recrystallization of UNS N07001(Waspaloy) alloy. This is manifested in the microstructure as a lower degree of recrystallization and in the rheological curve as a significant increase in deformation resistance.

(2) During the hot deformation process, the insufficient recrystallization structure caused by the final forging temperature being too low is prone to develop into a mixed grain structure in the subsequent heat treatment process, affecting the uniformity of the alloy’s microstructure.

The influence of solution temperature on grains of UNS N07001(Waspaloy)

(1) The finer the grain size, the greater the hardness value, which satisfies the Hol-Page formula.

(2) During the production process of bars, there is a large amount of residual cold stress at the edge of the bars, which will affect the surface hardness. Moreover, heat treatment below the static recrystallization temperature cannot eliminate the cold stress.

(3) If the solution is selected above the static recrystallization temperature, the residual cold stress will be largely eliminated, but it will also lead to recrystallization and growth of the grain size.

(4) The recrystallization of grains is accompanied by the elimination of residual cold stress. Therefore, by choosing an appropriate temperature, recrystallization of grains can occur, cold stress can be eliminated, and the grains will not grow significantly. It can make the grain size and hardness of the product cross-section tend to be consistent, and improve the comprehensive performance of the product.

The above is an introduction of UNS N07001(Waspaloy) nickel-chromium-cobalt superalloy. Our company’s official website (wellalloy.com) updates alloy-related information on a daily basis. We welcome everyone’s suggestions and exchanges.