Performance comparison of C276, C2000 and Inconel686

Tech Center 2025-08-22 174

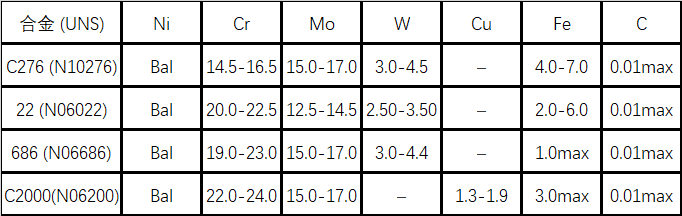

Analysis of chemical composition

C276, Hastelloy C2000 and Inconel686 are all nickel-based alloys. The Hastelloy series alloys possess incredible corrosion resistance and offer unparalleled quality in numerous industries. The main alloying elements of these metals are chromium, molybdenum and tungsten, each with its own unique properties: chromium can enhance corrosion resistance in oxidizing environments, molybdenum can enhance corrosion resistance in reducing environments, and chromium, molybdenum and tungsten improve the crevice corrosion resistance and pitting corrosion resistance of the alloys.

In conclusion, this mixture of metals and elements works together to provide excellent resistance to non-oxidizing acids and corrosion cracking. Hastelloy is particularly highly versatile: it is used in various applications where chimneys are paired with heat exchangers.

Alloy properties

(1) The chromium content of alloy 22(N06022) is higher than that of C276, indicating that it has higher corrosion resistance in oxidizing aqueous media when there is a high content of chloride ions.

(2) C2000(N06200) has the same chemical composition as Alloy59, but 1.6% copper is added. This enhances the alloy’s corrosion resistance to reducing environments, but at the cost of reduced thermal stability and weldability.

(3) Inconel686, an alloy made from the highest combination of chromium, molybdenum and tungsten, endows the alloy with excellent resistance to pitting and crevice corrosion. This was achieved at the expense of thermal stability and solderability.

The above is a comparison of the performance of C276, C2000 and Inconel686. Our company’s official website (wellalloy.com) updates alloy information daily. We welcome everyone’s suggestions and exchanges.