Introduction of UNS N06601(Inconel601)

Tech Center 2025-08-21 188

Introduction of UNS N06601 (Inconel601) alloy

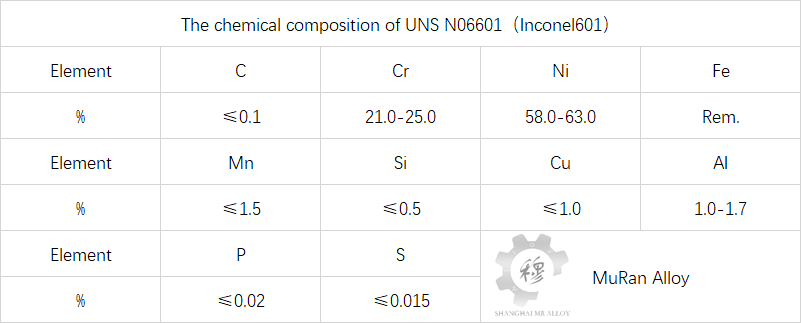

UNS N06601 (Inconel601) nickel-based alloy exhibits high mechanical properties and excellent oxidation resistance in high-temperature environments. It also has good corrosion resistance to many corrosive media and is widely used in metallurgy, heat treatment, chemical engineering, environmental protection and other fields.

UNS N06601 (Inconel601) is a face-centered cubic austenitic solid solution strengthening alloy of the N-i Cr series developed by Huntington Alloys in the 1970s. Its high chromium content makes it suitable for many corrosive and high-temperature environments. The addition of aluminium further enhances its strength and oxidation resistance. This alloy features excellent high-temperature oxidation resistance, good high-temperature mechanical properties and corrosion resistance. It is also easy to form, process and weld, and can be made into plates, tubes, wires, strips, rods, forgings, etc. It has been widely applied in fields such as petrochemicals, metallurgy, heat treatment and environmental protection.

Hot working performance of UNS N06601 (Inconel601)

(1) UNS N06601 (Inconel601) alloy exhibits excellent hot working performance within the range of 900 to 1250℃. Among them, within the range of 1050 to 1200℃, it not only has good thermoplasticity but also low deformation resistance, making it the most suitable for hot working.

(2) For the lower-temperature region, the limit deformation of UNS N06601 (Inconel601) alloy varies little at different deformation rates. At relatively low deformation rates, the corresponding deformation resistance is also low, and hot working can still be carried out under small deformation. At temperatures above 1275℃, the ultimate deformation of the alloy drops sharply and it cannot be hot-worked.

(3) It can be seen from the metallographic diagram of the thermal simulation sample that the alloy begins to show dynamic recrystallization in the temperature range above 850℃. The recrystallization rate is extremely fast at a relatively high temperature of 1200℃.

Welding process of UNS N06601 (Inconel601)

(1) During the welding process of UNS N06601 (Inconel601) nickel-based superalloy, to ensure the welding quality, it is advisable to adopt the welding method of small current rapid welding. Both too high and too low welding speeds will cause defects.

(2) During the welding process of UNS N06601 (Inconel601) nickel-based superalloy, when the welding line energy is approximately 3400J/cm, the matrix structure of the alloy does not change, and the weld seam structure and the base material produce a phenomenon of cross-crystallization. In the strengthening phase, the positions of some aluminum elements in the γ ‘phase are partially replaced by titanium elements to form Ni3(Al,Ti), and the titanium elements in the original carbides are also partially replaced by niobium elements to form (Nb,Ti)C.

(3) During the welding process of UNS N06601 (Inconel601) nickel-based superalloy, when the welding line energy reaches approximately 6500J/cm, in addition to γ phase, γ ‘phase and MC type carbides, M23C6 type carbides will be produced in the weld metal, and the carbides containing niobium elements in the weld will also undergo polymerization.

(4) The gas back protection clamp has the advantages of simple operation and good protection effect. It can well complete the internal gas protection during the butt assembly and welding of UNS N06601 (Inconel601) double P combustion tubes, ensuring the quality of the welding formation.

The above is an introduction of the UNS N06601 (Inconel601) alloy material, properties and process. Our company’s official website (wellalloy.com) updates alloy-related information on a daily basis. We welcome everyone’s suggestions and exchanges.