Introduction of UNS N06600(Inconel600)

Tech Center 2025-08-13 147

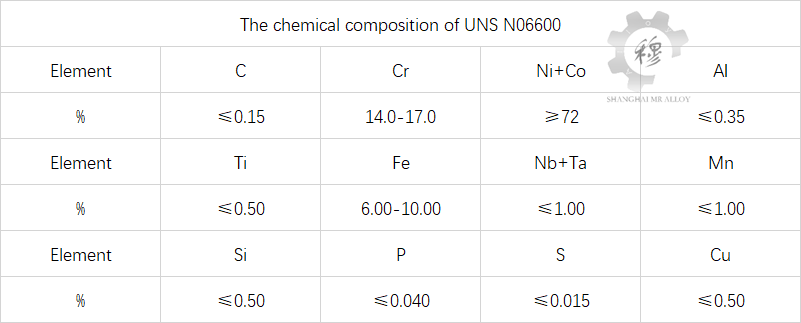

Introduction of UNS N06600(Inconel600) Superalloy:

UNS N06600(Inconel600) is a Ni-Cr-Fe-based solid solution strengthened deformable superalloy. It has good thermal strength and high plasticity below 800℃, and excellent high-temperature corrosion resistance and high-temperature resistance below 1000℃. Antioxidant properties. After long-term use, this alloy has a stable microstructure and excellent cold and hot working properties, welding performance and low-temperature mechanical properties. Alloys can be strengthened through cold working and can be joined by resistance welding, welding or brazing. It is suitable for engine combustion chambers below 700℃-800℃ and low-load anti-oxidation components below 1100℃. The main products include cold-rolled thin plates, hot-rolled thick plates, cold-rolled strip steel, wire rods, bars, tubes, discs, ring forgings, etc.

UNS N06600(Inconel600) superalloy has been used to manufacture rocket engine nozzle extension parts, high-pressure compressors for aero engines, stationary inner and outer rings, high-pressure guide vane orifices, seals, etc., and has also been applied in petrochemicals, nuclear reactors, chemical and food equipment, and electronic components. It is used for manufacturing exhaust pipes, carburizing containers, heat treatment equipment rollers, springs, heat exchanger tubes, reactor control rods and tubes.

Introduction of UNS N06600(Inconel600)

UNS N06600(Inconel600) alloy is resistant to corrosion from various corrosive media. Because it contains chromium, it has better corrosion resistance than pure nickel (alloy 200/201) under oxidizing conditions. Meanwhile, it contains a large amount of nickel, which endows the alloy with excellent corrosion resistance in reducing conditions and alkaline solutions. In addition, it has a strong resistance to stress corrosion cracking. It has good corrosion resistance in organic acids such as acetic acid, formic acid and stearic acid, and moderate corrosion resistance in inorganic acids. The high-purity water used in the first and second cycles of nuclear reactors has excellent corrosion resistance. It can resist the corrosion of dry chlorine and hydrogen chloride, and the working temperature can reach 650℃. At high temperatures, the annealed and solid-solution states of the alloy exhibit excellent oxidation spalling resistance and high strength in the air, and can withstand a temperature of 1100℃ in a continuous air oxidation environment. It can withstand a high temperature of 1150°C in a reducing gas (H2 or CO) without thorium (ionium). Oxidizing gases containing thorium (ions), such as air containing sulfite gas, can be used at a maximum temperature of 815°C. However, in reducing gases containing hydrogen sulfide, the upper limit temperature is 535℃. In addition, it will not become brittle even in a high-temperature environment of 550 to 750 degrees Celsius. Resistant to nitrogen, hydrogen, ammonia and carburizing gases. Although it is weak against wet chlorine and bromine, it is very effective in treating hydrogen chloride and chlorine at high temperatures. Hydrogen chloride can reach 540℃, and chlorinated gas can reach 510℃. However, when the oxidation-reduction conditions alternate, it can be corroded by some oxidizing media (such as green dead liquid).

Research on Heat Treatment Process of N06600(Inconel600)

(1) The finished heat treatment system for N06600(Inconel600) alloy tubes should be selected as 900℃×35 minutes in a vacuum annealing furnace, which can achieve good mechanical properties and grain size levels at both room and high temperatures.

(2) The N06600(Inconel600) alloy tube after vacuum heat treatment exhibits certain superplastic properties at 900℃.

The above is the relevant introduction of N06600(Inconel600). Our company’s official website (wellalloy.com) updates alloy information.