Introduction of Inconel625(UNS N06625)

Tech Center 2025-08-14 180

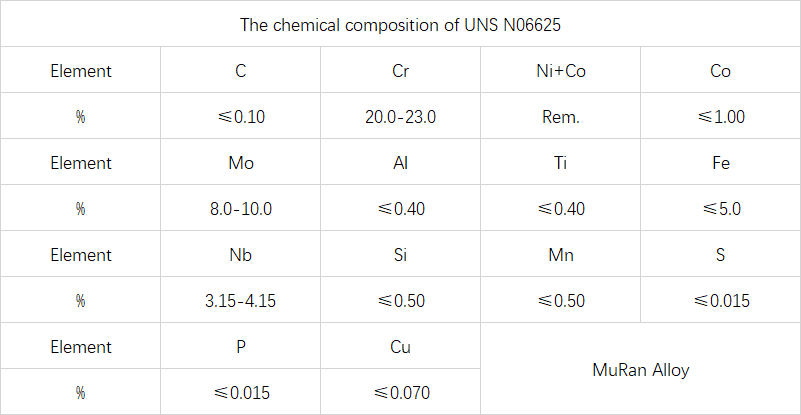

Introduction of Inconel625(UNS N06625) Alloy:

Inconel625(UNS N06625) alloy was developed in the 1950s to meet the demand for high-strength main steam pipe materials. This alloy is a solid-solution strengthened nickel-based deformable high-temperature alloy with molybdenum (Mo) and niobium (Nb) as the main elements. It features excellent corrosion resistance and oxidation resistance, and exhibits good tensile and fatigue properties from low temperatures to 980℃. Moreover, it is resistant to stress corrosion in salt spray atmospheres. This alloy cannot be strengthened by heat treatment. Its strength can be enhanced through cold working deformation. Alloy tubes are widely used in fields such as gas turbine engines, nuclear power equipment, and aerospace engines, and are manufacturing materials for key components in the aerospace, nuclear energy, petroleum, and chemical industries. Due to the high alloying degree of Inconel625(UNS N06625), its narrow hot deformation temperature range, poor hot plasticity, and large deformation resistance, the tube blank is prone to cracking or even breaking during heat transfer holes. Therefore, currently, Inconel625(UNS N06625) alloy seamless tubes are generally manufactured by hot extrusion technology for tube blanks. Then, through multiple cold rolling/cold drawing processing and heat treatment processes, qualified pipes of the required specifications are produced. The yield of alloy tubes can be increased and the production cost can be reduced by controlling the amount of cold deformation and the heat treatment process.

Application fields of Inconel625(UNS N06625) alloy

(1) Components of organic chemical process technology containing chlorides, especially in cases where acidic chloride catalysts are used.

(2) It is used for manufacturing digesters and bleaching tanks in the pulp and paper industry.

(3) Absorption towers, reheaters, flue gas inlet baffles, fans (moist), agitators, deflector plates and flues, etc. in the flue gas desulfurization system.

(4) It is used for manufacturing equipment and components applied in acidic gas environments.

(5) Acetic acid reacts with acetic anhydride.

Rolling Study of Inconel625(UNS N06625

(1) During the rolling process of Inconel625(UNS N06625) alloy, as the rolling deformation increases, the grain size of the material significantly decreases, and at the same time, a mixed grain size phenomenon occurs on the surface

(2) After rolling Inconel625(UNS N06625) alloy, the grain size in the core is significantly larger than that on the surface. It is because during the rolling process, the core and surface of the material are subjected to different amounts of shear deformation.

(3) After annealing treatment at 1150℃ for 5h, the grain sizes of the core and surface of Inconel625(UNS N06625) alloy tend to be consistent. Meanwhile, as the deformation increases, the grains of Inconel625(UNS N06625) alloy become finer after annealing treatment. The rolling of Inconel625(UNS N06625) alloy is hereditary.

That’s all about the nickel-based superalloy Inconel625(UNS N06625). We welcome relevant practitioners to discuss with the editor together.

Our company’s official website (wellalloy.com) updates relevant alloy information on a daily basis, hoping to be of assistance to relevant practitioners