Introduction of UNS N06002(HastelloyX)

Tech Center 2025-08-13 195

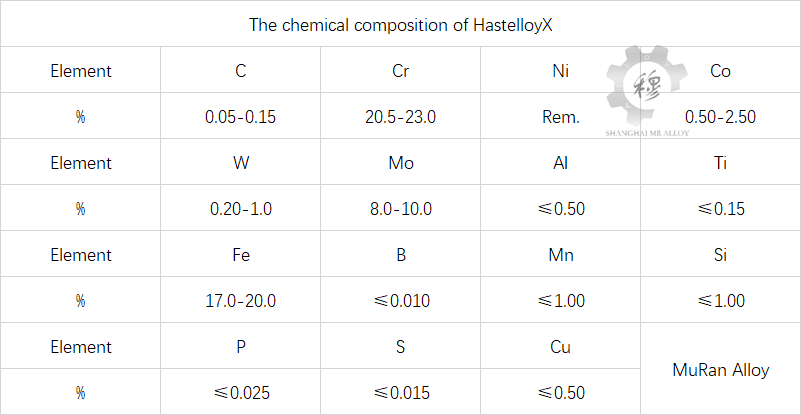

UNS NO6002(HastelloyX) Material Introduction:

It has excellent oxidation resistance and corrosion resistance, moderate durability and creep strength below 900℃, as well as good cold and hot working formability and weldability. It is suitable for manufacturing parts of the combustion chamber of aero engines and other high-temperature parts. It can be used for a long time at temperatures below 900℃, and the short-term working temperature can reach 1080℃. It is an alloy that can withstand certain stress and has the ability to resist oxidation or corrosion at high temperatures ranging from 600 to 1200℃. According to the base elements, they can be classified into iron-based superalloys, nickel-based superalloys and cobalt-based superalloys. According to the preparation process, they can be classified into wrought superalloys, cast superalloys and powder metallurgy superalloys. According to the strengthening methods, there are solid solution strengthening, precipitation strengthening, oxide dispersion strengthening and fiber strengthening.

UNS NO6002(HastelloyX) application fields:

Superalloys are mainly used to manufacture high-temperature components such as turbine blades, guide vanes, turbine discs, high-pressure compressor discs and combustion chambers for aviation, Marine and industrial gas turbines. It is also used in the manufacture of aerospace vehicles, rocket engines, nuclear reactors, petrochemical equipment and energy conversion devices such as coal conversion.

MuRan Industrial studied the creep behavior, microstructure changes and fracture mechanism of UNS NO6002(HastelloyX) alloy at three temperatures of 815, 850 and 900℃, and established the extrapation formula for the creep fracture strength of GH3536 alloy by using the Larson Miller (L-M) parameter method.

Research conclusion:

(1) At different test stress levels of 815, 850 and 900℃, the relationship between the steady-state creep rate of UNS NO6002(HastelloyX) alloy and stress can be expressed by a power-law relationship, with the corresponding stress indices being 6.4, 6.4 and 6.9 respectively. According to the stress index, the creep mechanism of UNS NO6002(HastelloyX) alloy under the test temperature and test stress in this study is mainly the slip and climbing of dislocations. The steady-state creep rate and creep fracture time conform to the Monkan-Grant relationship.

(2) During the creep test, second-phase particles precipitate at the grain boundaries and within the grains of the sample, forming R-type and W-type cracks at the grain boundaries and the second-phase particles. Based on the analysis of the allowable creep damage and the morphology of the creep fracture surface, it can be inferred that under the above test conditions, the creep fracture process involves the aggregation and growth of micropores, and eventually the specimen breaks due to necking.

(3) The extrapolation formula for creep fracture strength was established by using the L-M parameter method. According to the extrapolation formula, the creep fracture strength corresponding to the creep fracture time of 2000 hours of UNS NO6002(HastelloyX) alloy at 815℃ was obtained as 58MPa.

That’s all about nickel-based superalloy UNS NO6002(HastelloyX). We welcome relevant practitioners to discuss with the editor together.

Our company’s official website (wellalloy.com) updates relevant alloy information on a daily basis, hoping to be of assistance to relevant practitioners