Introduction of эп2220BД(GH4220)

Tech Center 2025-08-21 161

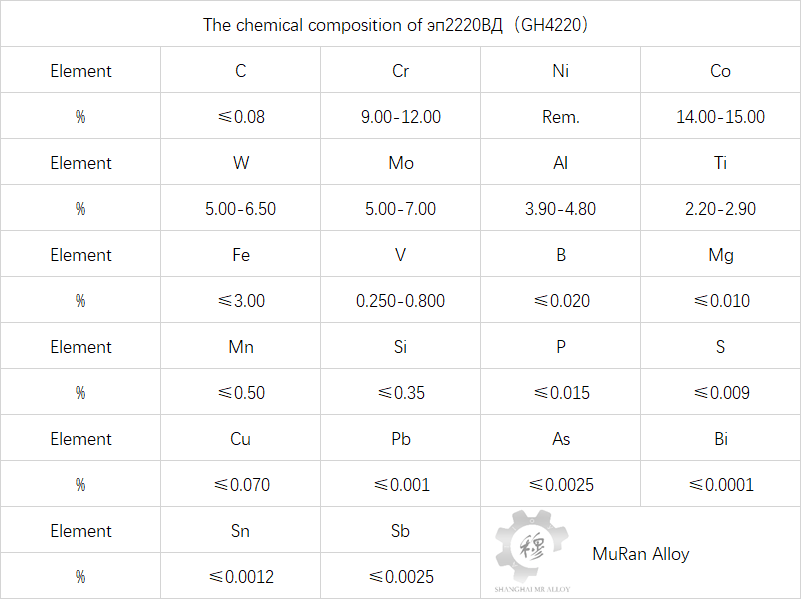

эп2220BД(GH4220)overview

эп2220BД(GH4220) is a ni-co-Cr-based precipitation-hardening deformable superalloy with a service temperature of 900 ° C -950 ° C. The aluminum and titanium elements added to the alloy form γ’ precipitation strengthening phases, with ω (γ’) reaching over 40%. At the same time, cobalt, chromium, tungsten and molybdenum elements are added for solid solution strengthening, and trace amounts of cerium, boron and magnesium elements are added for grain boundary strengthening. The alloy has high high-temperature strength and plasticity, and has good comprehensive performance. It is suitable for manufacturing gas turbine working blades with operating temperatures ranging from 900℃ to 950℃. The main products include hot-rolled bars for rotating parts and die-forged turbine blades.

эп2220BД(GH4220)alloy is a nickel-based aging precipitation-hardening high-temperature alloy that China has copied from the former Soviet Union, ХН51ВМТЮКФР⁃ВД. The alloy is based on Ni, with approximately 11%Cr, 15%Co, 6%W, 6%Mo, and 0.5%V added as solid solution strengthening elements, 4.5%AI and 2.5%Ti as aging strengthening elements, and C, B, Ce, and Mg as microalloying elements.

Application overview and characteristics of эп2220BД(GH4220)

The alloy has been used to manufacture the working blades of the first-stage turbine in aero engines, and the batch production and application have been going well.

The alloy undergoes a special curved grain heat treatment process to control the type and morphology of the second phase precipitated at the grain boundaries, thereby forming curved grain boundaries. This ensures a good match between the strength at the grain boundaries and within the grains, reduces the brittleness at the grain boundaries, and thereby significantly enhances the high-temperature plasticity and creep strength of the alloy.

Heat treatment system for эп2220BД(GH4220)

a) Standard heat treatment system:

1220℃±10℃×4h/AC+1050℃±10℃×4h/AC+950℃± 10℃×2h/AC, HB 341-285;

b) Curved crystal heat treatment system:

220℃×4 hours /(3-7)min→1100℃/AC+1050℃×4 hours /AC+950℃×2 hours /AC.

Solution cooling method for эп2220BД(GH4220)

Under the condition that the parameters such as temperature and time for solution and aging treatment in its standard heat treatment system (two-stage solution + aging) remain unchanged, the air cooling after the first stage solution treatment of GH4220 alloy bolts is changed to slow cooling (cooling for 24 minutes to 1100℃ and holding for 1 minute, then air cooling)

1) Under high-temperature and slow cooling conditions, curved grain boundaries were successfully obtained, and the grain boundary morphology changed from the straight grain boundaries under the standard heat treatment system to sawtooth-shaped curved grain boundaries.

2) The curved grain boundaries obtained under the slow cooling heat treatment system effectively enhance the grain boundary and intra-grain strength, which can delay the formation of cracks and reduce the crack propagation rate, improve the room temperature and high-temperature instantaneous tensile strength of GH4220 alloy bolts, and extend the high-temperature stress endurance time (13.5 hours).

The above is an introduction of эп2220BД(GH4220) nickel-cobalt-chromium superalloy material. Our company’s official website (wellalloy.com) updates alloy-related information on a daily basis. We welcome everyone’s suggestions and exchanges.