Introduction of эп202(GH4202)

Tech Center 2025-08-20 207

Overview of GH4202

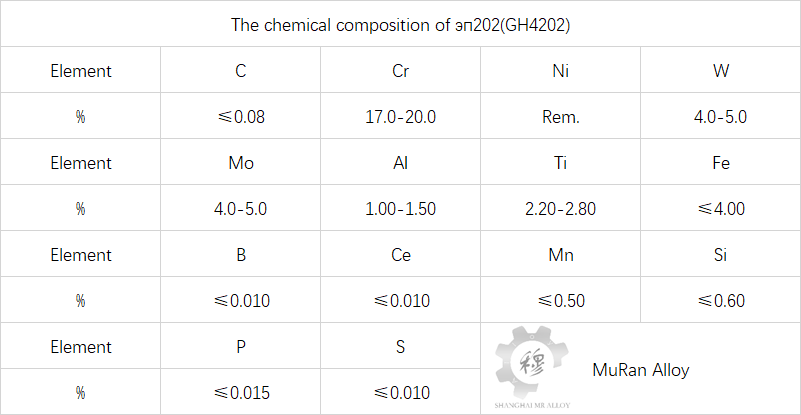

GH4202 is a Ni-Cr-based precipitation-strengthened deformable superalloy with a working temperature range of -253℃ to 800℃. Approximately 4% W(AI+Ti) was added to the alloy to form the γ’ aging strengthening phase, about 9% w(W+Mo) was added for solid solution strengthening, and a small amount of boron and cerium elements were added to strengthen and purify the grain boundaries. The alloy has excellent comprehensive mechanical properties and a stable microstructure. It has high corrosion resistance and oxidation resistance, as well as excellent resistance to oxygen-rich erosion. The alloy has excellent welding performance and is a typical multi-purpose high-temperature alloy material. The main products include bars, forgings, plates, tubes and wires, etc.

Overview and Features of GH4202 Applications

Alloys have been used to manufacture dozens of components of new high-thrust liquid rocket engines, such as turbine rotors, rectifying grids, turbine ball shells, bellows and gas pipelines, and have been in good use. Alloys can also be widely applied in fields such as aviation, nuclear energy, petroleum and chemical engineering, where heat-resistant load-bearing parts and welded parts with high requirements for corrosion resistance and oxidation resistance are needed.

The alloy is required to be welded in the solution state, and heat treatment is needed after welding to eliminate residual stress. No harmful phases precipitated from the alloy after long-term high-temperature aging.

Smelting process of GH4202

The vacuum induction furnace + vacuum self-consumption remelting melting process is adopted

Heat treatment system for GH4202

a) Cold-rolled thin plate, (1060-1120)℃/AC+850℃×5h/AC, where the solution holding time is determined according to the thickness of the plate;

b) Hot-rolled plate, (1090-1150)℃/AC+850℃×5h/AC, where the solution holding time is determined according to the thickness of the plate;

c) Bars and forgings, (1060-1150)℃×5h/AC+(800-865)℃×5h/AC;

d) Seamless tubes, 1100℃×(5-10)min/ rapid cooling +850℃×5h/AC.

Supply status of GH4202

Hot-rolled plates and cold-rolled thin plates are supplied after solution treatment, pickling, straightening and edge trimming. Hot-rolled and forged bars are generally supplied without heat treatment. Seamless tubes are supplied after solution treatment, pickling and straightening. Forgings can be supplied after solution treatment or after rough machining.

Fastener bars, Grade A: supplied after hot rolling + annealing + grinding or turning; Grade B: Supplied after cold drawing and, if necessary, after grinding. Grade C: Supplied after cold drawing + solution treatment + polishing; Grade D: Supplied after cold drawing + solution treatment + aging + grinding or turning.

The influence of GH4202 solution temperature on it

(1) After solution treatment at 1050-1075℃, the grain size change of GH4202 alloy was not obvious. When the temperature reached 1150℃, the grains grew uniformly. The solution temperature has no significant effect on the morphology, content and size of the γ’ phase in the alloy. The quantity of boron and carbides at the alloy grain boundaries decreased significantly with the increase of solution temperature, transforming from chain-like to isolated granular. When the temperature rises to 1100℃, the chain-like carbon and borides on the grain boundaries partially re-dissolve, and the unre-dissolved granular borides gradually coarser. At 1150℃, the boron and carbides on the original fine-grained grain boundaries basically redissolve, the migration speed of the grain boundaries increases, and the grains grow rapidly.

(2) With the increase of solution temperature, the tensile strength of GH4202 alloy at both room temperature and high temperature shows a decreasing trend, especially the maximum reduction in yield strength is nearly 20%. The room-temperature surface shrinkage of the alloy decreases with the increase of solution temperature, with a maximum reduction of nearly 30%, but the change in room-temperature fracture elongation is not significant. At 700℃, both the reduction of area and the elongation at break of the alloy increase first and then decrease with the rise of solution temperature.

The above is an introduction to GH4202 nickel-chromium superalloy material. Our company’s official website (wellalloy.com) updates alloy-related information on a daily basis. We welcome everyone’s suggestions and exchanges.