Introduction of XH68MBKTЮP(RUS)GH4099

Tech Center 2025-08-17 163

Introduction of XH68MBKTЮP(RUS)GH4099 alloy

In modern aerospace and energy fields, the application of superalloys is becoming increasingly widespread, and the performance requirements for superalloy components are also getting higher and higher. It is necessary to continuously optimize and innovate the forming process of superalloys. If a certain model extensively adopts a high-temperature alloy hot cabin structure, the surface radiation equilibrium temperature of the cabin will exceed 900℃ over a large area during flight. Therefore, high-temperature alloys with higher temperature resistance are selected for the cabin materials, such as XH68MBKTЮP(RUS)GH4099.

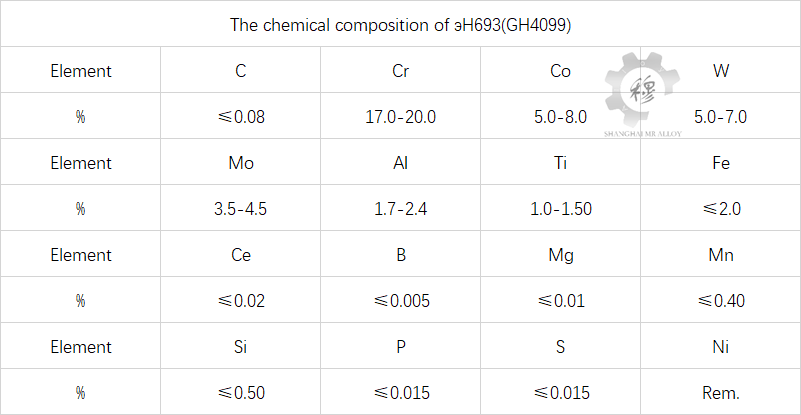

XH68MBKTЮP(RUS)GH4099 alloy is an age-hardening high-temperature alloy. It is a dispersion strengthening material with high thermal strength, based on Ni and Cr, strengthened by solid solution with W, Mo and Co, strengthened by aging with Al and Ti, and strengthened by intergranular with B and Ce. The alloy has a complex phase composition. Besides the matrix γ phase, it mainly consists of γ ‘, Ti (CN) type nitrides, and σ phase and μ phase that appear after long-term aging. This alloy is mainly used in high-temperature strength load-bearing parts such as diffusers in the combustion chambers of aero engines, and its service temperature can reach about 1000℃.

XH68MBKTЮP(RUS)GH4099 arc manufacturing process

1) When Ar gas is used as the protective gas in arc additive manufacturing, the liquid metal of XH68MBKTЮP(RUS)GH4099 superalloy has poor fluidity, and holes that have not been fused are prone to occur during the forming process. However, using He gas as the protective gas can effectively avoid such defects.

2) The microstructure of XH68MBKTЮP(RUS)GH4099 superalloy arc additive manufacturing material shows obvious anisotropy. Among them, continuous columnar dendrites are displayed perpendicular to the additive direction, while equiaxed crystal structure is presented parallel to the additive direction. Within the equiaxed crystal, there exist dendritic substructures. A large amount of γ ‘strengthening phase and MC carbides are dispersed and distributed at the equiaxed grain boundaries and within the grains.

3) Mechanical tests at normal temperature and 900℃ high temperature showed that the tensile strength and elongation after fracture at room temperature of XH68MBKTЮP(RUS)GH4099 high-temperature alloy arc additive manufacturing material both met the requirements of the GB/T14996-2010 “Cold-rolled High-temperature Alloy Sheets” standard. However, due to the presence of low-melting-point eutectic intergranular dendrites, the elongation after fracture at 900 ° C is lower than the standard requirement, approximately 12%.

XH68MBKTЮP(RUS)GH4099 high-temperature endurance performance

1) When the contents of Al and Ti in XH68MBKTЮP(RUS)GH4099 alloy remain unchanged, increasing the alloy contents of W, Mo and Co is beneficial to enhancing the alloy strength.

2) Controlling the Mg element in XH68MBKTЮP(RUS)GH4099 alloy within an appropriate range is beneficial for improving the alloy’s creep performance

The above is an introduction to the chemical composition and processing technology of XH68MBKTЮP(RUS)GH4099 nickel-based alloy. Our company ‘s official website (wellalloy.com) updates relevant alloy information on a daily basis. We welcome exchanges among industry insiders.