Introduction of GH3128

Tech Center 2025-08-11 215

Introduction of GH3128 Superalloy

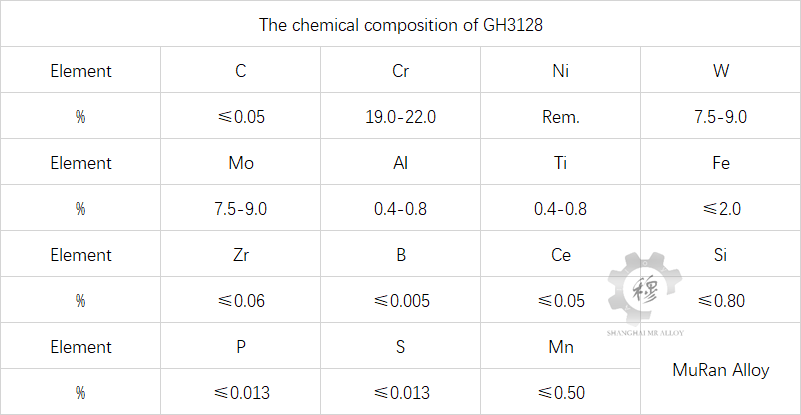

GH3128 alloy is a nickel-based superalloy independently developed in China. This alloy is mainly strengthened by solid solution using W and Mo, and the grain boundaries are strengthened by elements such as B, Ce, and Zr to enhance the strength of the alloy. It belongs to solid solution strengthened nickel-based superalloys. GH3128 alloy features high plasticity, high creep strength, excellent oxidation resistance, stamping and welding performance. Its comprehensive performance is superior to that of similar nickel-based solid solution alloys (such as GH3044, GH3536, etc.). It is mainly used for high-temperature structural components such as aero engines, gas turbine engines and afterburner shells that are used for a long time with a capacity of 950t or less. In recent years, GH3128 alloy is expected to become the main structural material for components such as ultra-high temperature gas-cooled reactors and intermediate heat exchangers.

The relationship between milling force, surface roughness and cutting parameters of GH3128

1) In the force signal processing of the cutting process, the use of power spectral density method and wavelet transform technology to reduce the noise of the cutting force signal can improve the recognition of the force signal in the signal.

2) The influence of cutting parameters on cutting force: There is no linear relationship between surface roughness Ra and cutting parameters

Introduction of GH3128

1) Pre-oxidation treatment at an appropriate temperature can effectively enhance the high-temperature cyclic oxidation resistance of GH3128 alloy.

2) The performance of GH3128 alloy after pre-oxidation treatment mainly depends on the combined effect of two factors. One is to selectively oxidize the element Cr on the alloy surface to form a dense and uniform protective pre-oxidation film, thereby enhancing the sample’s resistance to high-temperature oxidation. Second, the grain boundary segregation of Ti and Cr elements in the alloy intensifies, accelerating grain boundary oxidation and generating defects such as microcracks, thereby reducing the sample’s resistance to high-temperature cyclic oxidation.

3) GH3128 alloy pre-oxidized at 900℃ has the best resistance to high-temperature cyclic oxidation. After pre-oxidation at this temperature, a dense and uniform Cr2O3 film will form on the surface. At this temperature, the grain boundary segregation of alloying elements Ti and Cr is not significant, and their resistance to high-temperature cyclic oxidation damage is relatively weak.

Every day, we update relevant alloy information on our official website (wellalloy.com), hoping to be helpful to relevant practitioners

The above is the relevant introduction about the high-temperature total chemical composition and performance of GH3128.