Introduction of Udimet Alloy L-605(UNSR30605)

Tech Center 2025-08-09 143

Overview of UNSR30605

UNSR30605 is a Co-Cr-Ni-based solid solution strengthened deformable superalloy, with a service temperature below 1000°C. Solid solution strengthening is carried out by adding 20% ω(Cr) and 15% ω(W) to the alloy. The alloy has moderate creep and creep strength below 815°C, excellent oxidation resistance below 1090°C, and good processing and welding properties. The main products include hot-rolled and cold-rolled plates, cold-rolled strips, bars, forgings, wires and precision castings.

Cobalt-based superalloys exhibit excellent stability and high strength at high temperatures and are widely used in turbine blades and internal guide vanes of aero engines. Additionally, due to their good biocompatibility, they have also attracted much attention in the biomedical field. UNSR30605 alloy is a 20Cr, 15W solid solution strengthened non-magnetic cobalt-based superalloy, mainly used for manufacturing engine guide vanes, turbine outer rings, outer walls, vortices, sealing plates and other components. Domestic and foreign alloys with similar compositions include: L605, HS25, WF-11, ASTM F90, KC20WN.

Once these parts malfunction, it will bring very serious consequences and losses. Therefore, it is of great significance to study the thermal deformation behavior of GH5605 alloy.

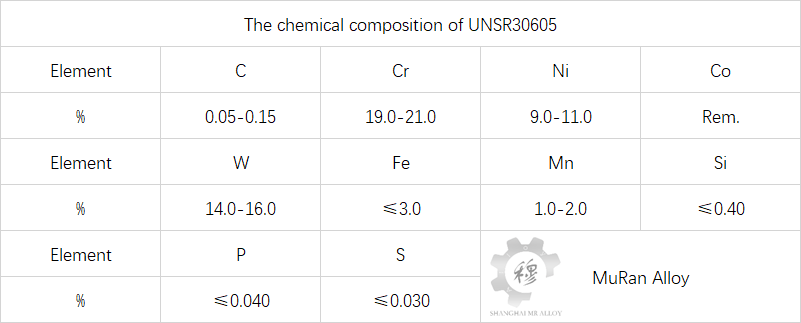

The chemical composition of UNSR30605

The thermal deformation process of UNSR30605

1)During the hot compression deformation process, the true stress-true strain curve of UNSR30605 alloy belongs to the work hardening type + dynamic recovery type. The true stress-true strain curve is mainly divided into three stages, namely stage I of intense work hardening, stage II of gentle work hardening, and Stage III of steady-state rheology.

2)The correlation coefficient (R) and the average relative error (δ) of the UNSR30605 alloy constitutive model were calculated using the Arrhenius constitutive model, which were 0.95 and 11.99% respectively. It was also predicted that the stress had a good correlation at high temperatures.

3)Based on the dynamic material model, the hot working diagram of UNSR30605 alloy was constructed, and the accuracy of the processing diagram was verified in combination with the microstructure. The results show that a strain rate of 0.01 to 0.1s −1 and a temperature of 1055 to 1200℃ are the favorable processing zones for UNSR30605 alloy.

The above is an introduction of UNSR30605 high-temperature cobalt-based alloy. (wellalloy.com) updates alloy information daily. Welcome everyone’s advice and exchanges.