Introduction of BЖ98(RUS)GH3044

Tech Center 2025-08-11 146

Introduction of BЖ98(RUS)GH3044:

BЖ98(RUS)GH3044 alloy is a solid solution strengthened nickel-based superalloy (rich in W and Cr elements), which can maintain high strength, plasticity and good oxidation resistance below 900 ℃. It is widely used in aerospace and can be used to make high-temperature components (such as gas generators, etc.). The microstructure of this alloy after solution treatment is single-phase austenite + carbides (including CrM23C6 phase and WM6C phase rich), and usually also contains a small amount of TiN and TiC phases. Adding a small amount of C forms carbides between grains, thereby preventing grain coarsening and crack initiation, and playing a role in strengthening grain boundaries and enhancing fracture strength.

BЖ98(RUS)GH3044 forming properties.

1) The forging heating temperature of BЖ98(RUS)GH3044 steel ingot is 1170℃±10℃, and the terminal temperature shall not be lower than 900℃. The heating temperature for slab rolling is 1190±10℃, and for thin plate rolling, it is 1130℃±10℃. The total reduction rate of cold rolling for thin plates with a final rolling temperature above 800℃ is approximately 30%.

2) Sheet BЖ98(RUS)GH3044 has good stamping process performance. The limit deep drawing coefficient of the supply state of cold-rolled thin plates is k limit =2.06.

BЖ98(RUS)GH3044 part heat treatment process.

The intermediate heat treatment temperature is 1140℃±10℃, held for 3 to 5 minutes, and air-cooled. The final heat treatment temperature is determined based on the working conditions of the components. For components requiring good thermal fatigue performance, solution treatment is carried out at 1150℃, held for 3 to 5 minutes, and air-cooled. For high-temperature forced components, solution treatment is conducted at 1200℃, held for 3 to 5 minutes, and air-cooled.

BЖ98(RUS)GH3044 physical properties introduction.

Alloy BЖ98(RUS)GH3044 is a solid solution strengthened nickel-based antioxidant alloy, which is smelted in an electric arc furnace, a non-vacuum induction furnace, or a vacuum induction furnace + electroslag remelting or vacuum arc remelting process. It has high plasticity and moderate thermal strength below 900 ℃, and also features excellent oxidation resistance and good stamping and welding process performance. It is suitable for manufacturing sheet metal stamping and welding structural components of the main combustion chamber and afterburner of aero engines that operate for a long time below 900 ℃, as well as installation edges, conduits, guide vanes and other parts, and heat shields, guide vanes, etc.

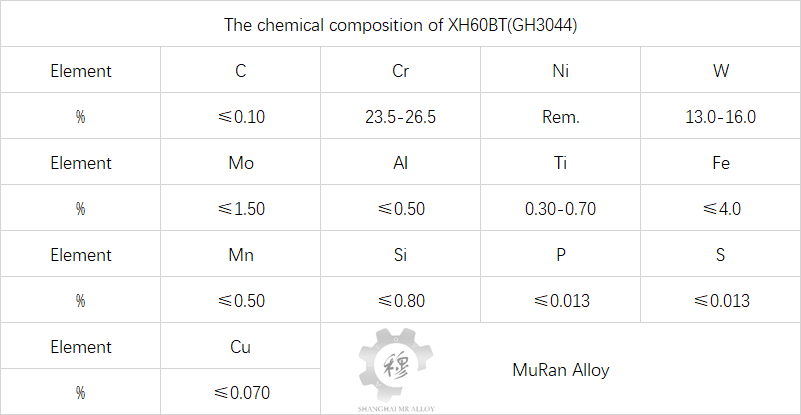

Similar grades: Russian z И686, XH60BT, BЖ98, Chinese GH3044 /GH44.

Physical properties: Melting temperature range: 1352-1375 ℃; At 100, 200, 300, 400, 500, 600, 700, 800, 900 and 950 ℃, the corresponding thermal conductivity λ is 11. 7. 13 0, 14. 2. 15 9. 17 2. 18 4. 19 7. 21 8. 24 7. 25 1 W/( m·℃) ; At 100, 200, 300, 400, 500, 600, 700, 800, 900 and 1000 ℃, the corresponding specific heat capacities c are 440, 461, 482, 503, 524, 545, 545, 566, 587 and 629 J /(kg·℃), respectively. At temperatures ranging from 20 to 100, 20 to 200, 20 to 300, 20 to 400, 20 to 500, 20 to 600, 20 to 700, 20 to 800, 20 to 900, and 20 to 1000 degrees Celsius, the corresponding coefficient of linear expansion α is 12. 5. 12 35. 12. 85, 13 10, 13 31, 13 50, 14 30, 14 90. 15. 60, 16 28 10-6 ℃ -1 Density ρ = 8.89 g /cm ³; The alloy is non-magnetic.

The above is an introduction of BЖ98(RUS)GH3044.

All relevant practitioners are welcome to discuss together. (wellalloy.com) will frequently update experiments and knowledge related to alloys.