Introduction of UNS R30188(Udimet alloy 188)

Tech Center 2025-08-19 155

Superalloys refer to metallic materials that can operate for a long time at temperatures above 600℃ and under certain stress. They are often classified into three types based on the difference in their matrices: iron-based superalloys, nickel-based superalloys, and cobalt-based superalloys. Superalloys have excellent fatigue resistance, fracture toughness and plasticity. Moreover, they have sufficient high-temperature strength when used at high temperatures and outstanding oxidation resistance and corrosion resistance in other environments at high temperatures. These are crucial advantages for materials used at high temperatures. Therefore, superalloys are widely used in the aerospace field.

Superalloys do not improve their performance by altering their chemical composition, but mainly by enhancing the production and processing techniques to achieve better alloy properties. Therefore, new types of alloys have rarely emerged in recent years. The development history of superalloys can be divided into four stages according to their production and processing techniques: wrought superalloys, common cast superalloys, directionally solidified superalloys, and single crystal superalloys.

In recent decades, with the continuous development and progress of science and technology, the operating temperature of high-temperature alloys has increased from the initial 750℃ to around 1200℃, and their high-temperature performance has also been greatly improved. This has gradually expanded the application scope of high-temperature alloys. Besides being mainly used in the engine field, high-temperature alloys have also begun to be applied in thermal protection systems. Form the high-temperature alloy thermal protection system that is currently widely used in reusable launch vehicles and hypersonic aircraft.

The cobalt-based superalloy system is mainly composed of Co-Ni-Cr austenite dominated by Co. Alloying elements such as Ni, Fe, Co, and Mn need to be added to the alloy to promote the formation of a face-centered cubic austenite matrix, ensuring that the austenite structure can still stably exist at low temperatures. In addition, the addition of Cr and Al to the alloy can significantly enhance its oxidation resistance, which is particularly important for cobalt-based superalloys applied in high-temperature and complex atmospheres. Adding Ti to alloys can enhance their resistance to thermal corrosion. Elements such as Al, Ti, and Nb that form intermetallic compounds in alloys, as well as B elements that tend to aggregate at grain boundaries, can all play a strengthening role.

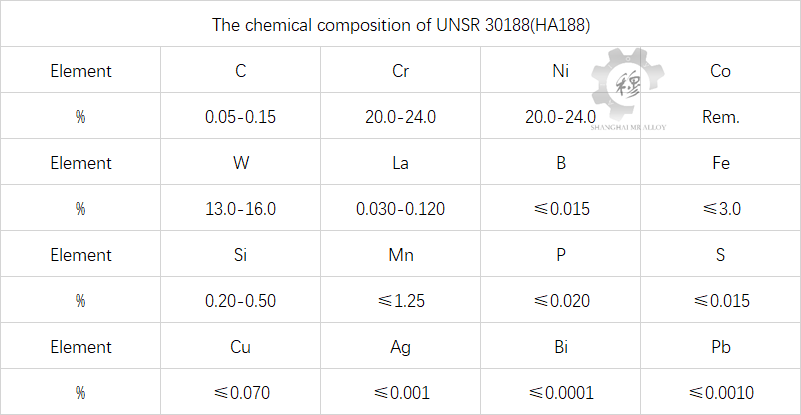

UNS R30188 (Udimet alloy 188) superalloy is a solid-solution strengthened cobalt-based superalloy. It features excellent high-temperature oxidation resistance and satisfactory processing, forming, and welding properties. It is suitable for manufacturing parts in aero engines that require high strength below 980 ° C and oxidation resistance below 1100 ° C.

The main functions of each element in UNS R30188 (Udimet alloy 188)

1) Co

As a matrix, it is compatible with various alloying elements and can improve thermal stability and manufacturing performance

2) Ni

The main solid solution strengthening elements

3) Cr

The main solid solution strengthening elements and carbide-forming elements are the primary elements that form a dense oxide film and enhance the alloy’s resistance to oxidation and corrosion

4) Mn

Expand the γ region and stabilize austenite

Enhance the adhesion between the oxide film and the substrate, thereby improving the anti-peeling ability and enhancing the anti-oxidation performance

It is used as a refining agent during smelting to reduce the harmful effects of S

Aggregation in the welding melting zone can reduce the tendency of hot cracking and improve the welding performance

5) W

Strong solid solution strengthening

Increase the diffusion activation energy and slow down the high-temperature diffusion of Al, Ti and Cr

6) Si

It has a small diffusion coefficient, and its affinity for oxygen is greater than that for chromium. It passivates between the Cr2O3 film and the substrate to form a SiO2 film, which hinders the outward diffusion of Cr ions in the substrate and enhances the antioxidant performance (beneficial).

Excessively lowering the recrystallization temperature of the alloy is not conducive to its high-temperature strength

Promoting the formation of Laves phase and G phase is detrimental to the creep strength and crack resistance of the matrix structure

7) Fe

Improve the compatibility of alloying elements with the matrix

8) C

It forms fine carbides with alloying elements and disperses them in the matrix to play a strengthening role

It forms carbides with Ti and Cr, reducing the degree of alloying. However, the formation of Cr carbides lowers the oxidation resistance, and the excessive presence of TiC or Ti (CN) causes metallurgical defects

C undergoes an oxidation reaction at high temperatures and overflows, destroying the compactness of the oxide film on the metal surface

9) Trace elements

Carbon stabilizer

The above is an introduction to the functions of each element in the chemical composition of UNS R30188 (Udimet alloy 188). Our company’s official website (wellalloy.com) updates alloy-related information daily. We welcome everyone’s suggestions and exchanges.