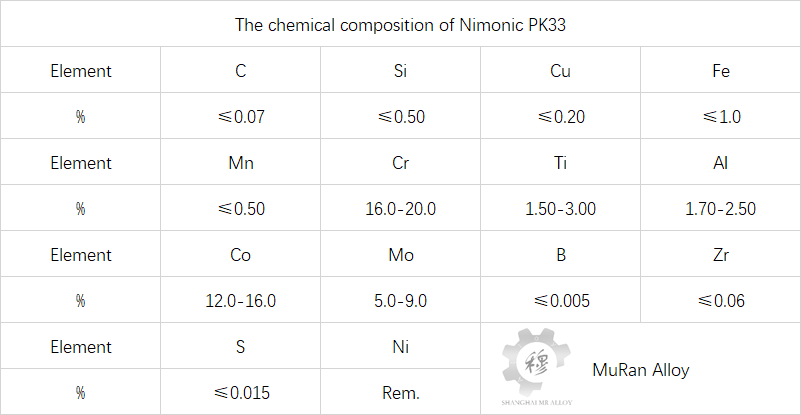

The chemical composition of Nimonic PK33

Tech Center 2025-08-03 124

Nimonic PK33 is a vacuum-treated nickel-based alloy designed to provide a sheet material with improved ductility and high creep strength in welded components, replacing Nimonic80A and 90 alloys.

Nimonic PK33 alloy features extremely high thermal shock resistance and thermal fatigue resistance, as well as excellent weldability. Therefore, it is suitable for the combustion chambers, nozzle tubes and reheating systems of high-performance gas turbine engines.

Although the alloy was developed as sheet material, the related forgings and ring components are also necessary. Now, the standard practice for producing forging billets, bars and sections is to use consumable electrode vacuum arc melting process.

The welding technique of this alloy is similar to that commonly used in other nickel-based age-hardening alloys.

The density of this alloy is ρ=8.21g/cm³.