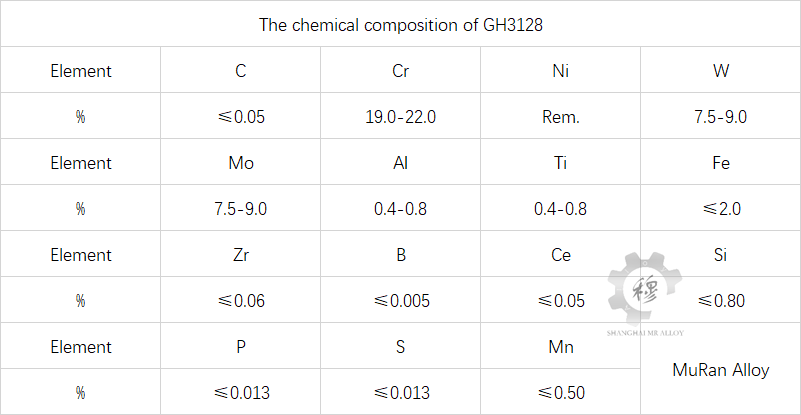

The chemical composition of GH3128

Tech Center 2022-06-14 180

GH3128 (GH128) is a nickel-based alloy that is strengthened by solid solution with tungsten and molybdenum, and by grain boundary with boron, cerium and zirconium. It features high plasticity, high permanent creep strength, as well as excellent oxidation resistance, stamping and welding properties. Its comprehensive performance is superior to that of similar nickel-based solid solution alloys such as GH3044 and GH3536. It is suitable for manufacturing high-temperature parts such as flame tubes, afterburner shells and regulating components of aero engine combustion chambers that operate at 950℃ for a long time. The main products include cold-rolled thin plates, hot-rolled thin plates, bars, forgings, wires and tubes. The solid solution temperature at the factory is 1140 to 1180℃, and it is air-cooled. The high-temperature performance was tested after supplementary solution treatment at 1200°C. Cold-rolled sheet 0.8-4.0mm, hot-rolled sheet 4-14mm, cold-drawn welding wire Φ0.3-10mm. Solution pickling of cold-rolled and hot-rolled plates; The welding wire is in a cold-drawn, semi-hard or solution and pickling state. Electroslag remelting in non-vacuum or vacuum induction furnaces. This alloy is suitable for manufacturing parts of the combustion chamber and afterburner of aero engines that operate below 950℃, with good results.