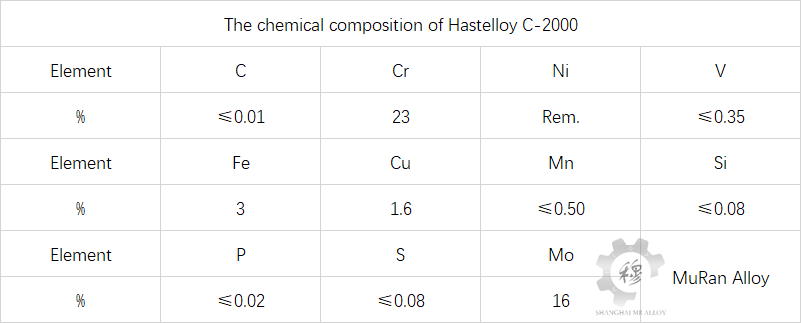

The chemical composition of Hastelloy C-2000

Tech Center 2025-08-04 123

Hastelloy C-2000 alloy, an optimized alloy developed to expand the application range of materials, originated from a conceptual idea of adding copper to the already well-established Ni-Cr-Mo alloy. Since it entered the market at the end of 1995, it has continuously received great recognition from the market, which is attributed to its inherent multi-purpose nature. Technological innovations not only enhance the alloy’s resistance to water corrosion but also expand the overall application scope of the Ni-Cr-Mo family alloys.

This new material is designed to resist more corrosive chemicals, including sulfuric acid, hydrochloric acid, and fluoric acid. Unlike the previously optimized Ni-Cr-Mo alloy, which could only resist oxidizing or reducing acids, the C2000 alloy has corrosion resistance in both environments. The combined effect of molybdenum and copper (at 16% and 1.6% levels respectively) endows the alloy with excellent resistance to corrosion by reducing media, while the high chromium content (23%wt) ensures resistance to corrosion by oxidizing media. From an engineering perspective, the C-2000 offers great potential for enhancing production. When used in the original Ni-Cr-Mo alloy, its enhanced corrosion resistance can achieve a longer equipment service life under the same material thickness and a higher safety factor under more severe conditions. The improvement of anti-corrosion performance in all aspects enables

The equipment can be used for multiple purposes (reactors, heat exchangers, valves, pumps, etc.), thereby achieving a greater return on investment. For instance, a reactor can adapt to another working condition where a hydrochloric acid mixture is then transformed into a nitrate mixture. Due to the multiple capabilities of C-2000, it is the best nickel-based alloy material that can adapt to various processes.

The density of this alloy is ρ=8.50g/cm³.