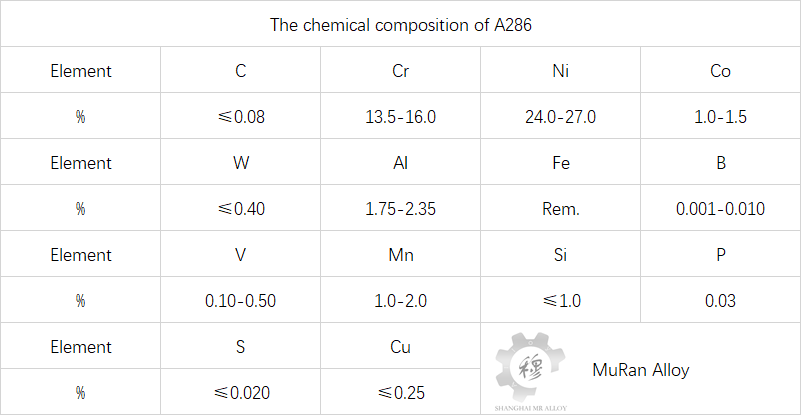

The chemical composition of A286

Tech Center 2022-06-14 213

A286 is a stable γ -austenitic matrix, precipitation-strengthened iron-nickel-based deformable superalloy composed of 15Cr-25Ni-Fe as the base. It features high strength and excellent corrosion resistance at room temperature, as well as high yield strength and creep strength at high temperatures. Its maximum service temperature is 650 ° C It is often used to manufacture aircraft load-bearing components that operate for a long time at temperatures below 650℃, such as turbine discs, blades and fasteners, etc. In recent years, GH2132 alloy cold-drawn bar and wire have often been used in the production of domestic fastener products with a strength grade of 1100MPa, such as hollow rivets, bolts and nuts, etc.

Up to now, the usage rate of high-temperature alloys in the field of aero engines has exceeded 50%. A286 alloy is a new type of iron-based superalloy developed in China. This alloy is strengthened by the precipitation of intermetallic compound γ’ phase (Ni3AlTi) through aging. After solution aging, it has a series of excellent comprehensive properties, such as high yield strength, good thermal hardness and high creep strength.