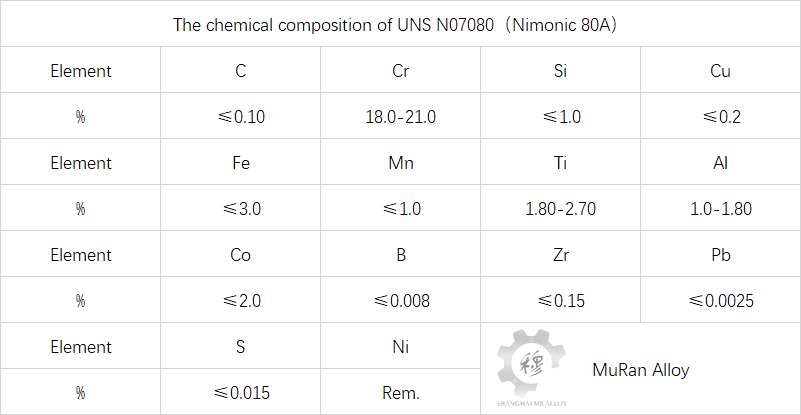

The chemical composition of UNS N07080(Nimonic 80A)

Tech Center 2025-08-02 164

Nimonic 80A is a forged and age-hardened nickel-chromium alloy, reinforced with titanium, aluminum and carbon, specifically developed for use at temperatures up to 815 ° C (1500°F). It is produced through high-frequency melting in the air and casting for extrusion billets. Electroslag refining materials are billets used for forging. There is also a vacuum refined version available for selection. Nimonic 80A alloy is currently used in gas turbine components (plates, rings and discs), bolts, nuclear boiler tube supports, die-casting inserts and core molds, as well as automotive exhaust valves.

The density of this alloy is ρ=8.19g/cm³.