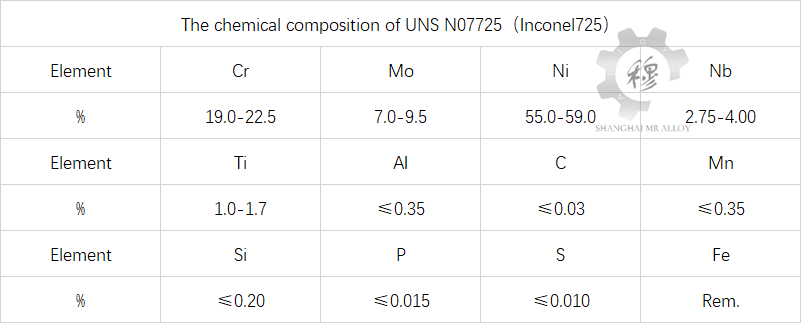

The chemical composition of UNS N07725(Inconel725)

Tech Center 2025-07-29 123

Inconel725 is a nickel-chromium-molybdenum-niobium alloy with extremely high corrosion resistance and can achieve extremely high strength through age hardening. It basically has the same corrosion resistance as Inconel625, which is widely used in various extremely corrosive environments. The strength of age-hardened Inconel725 is approximately twice that of annealed Iconel625. Because the strength of Inconel625 is achieved through heat treatment rather than cold working, its toughness and ductility remain very high. In addition, strength can be applied to large or uneven cross-sections that cannot be strengthened by cold working.

The high content of nickel and chromium provides corrosion resistance in both reducing and oxidizing environments. A large amount of molybdenum content enhances resistance to reducing media and provides high resistance to pitting and crevice corrosion. In addition, the combination of elements endows the alloy with the ability to resist hydrogen embrittlement and stress corrosion cracking.

The features of Inconel725 are suitable for a range of applications that require excellent corrosion resistance and high strength. This alloy is used for hangers, landing nozzles, side pocket mandshafts and polished hole receivers in acid gas services, and can resist the influence of hydrogen sulfide, chlorides and carbon dioxide. It is also suitable for high-strength fasteners in Marine applications, and can resist corrosion, pitting and crevice attacks in seawater.

The density of this alloy is ρ=8.31g/cm³.