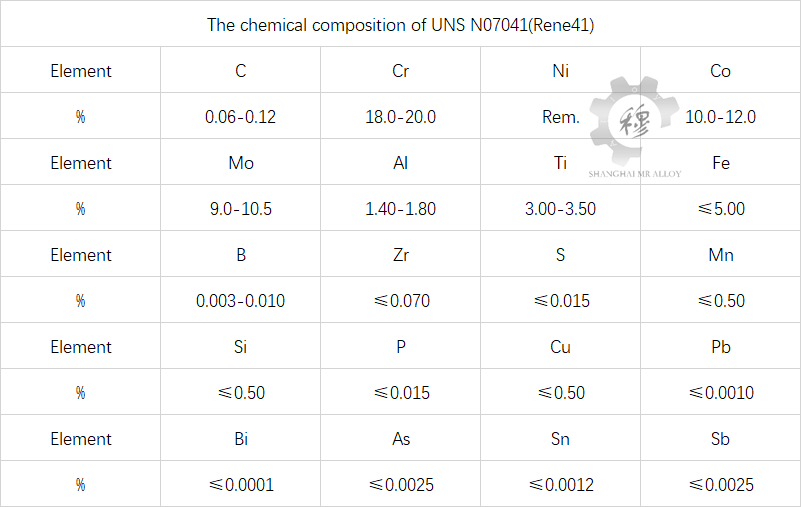

The chemical composition of UNS N07041(Rene41)

Tech Center 2025-07-29 131

UNS N07041(Rene41) is a Ni-Cr-Co-based precipitation-hardening deformable superalloy, mainly featuring age-precipitated γ’ phase and M6C type carbides as the primary strengthening phases, with a service temperature below 980 ° C. The alloy exhibits high tensile, creep and endurance strength, yield resistance and fatigue resistance, as well as excellent oxidation resistance within the range of 650℃ to 900℃. It is one of the sheet alloys with the highest mechanical properties for use below 980℃. The alloy has excellent machinability and is suitable for manufacturing components such as turbine discs, guide vanes, combustion chamber sheet load-bearing parts, turbine rotors, guides, fasteners and high-temperature springs for aviation and aerospace engines that require high strength below 870℃ and oxidation resistance below 980℃. The main products include hot-rolled and forged bars, plates and strips, wires, disc forgings and rings, etc.

The density ρ of UNS N07041(Rene41) is 8.27g/cm³.