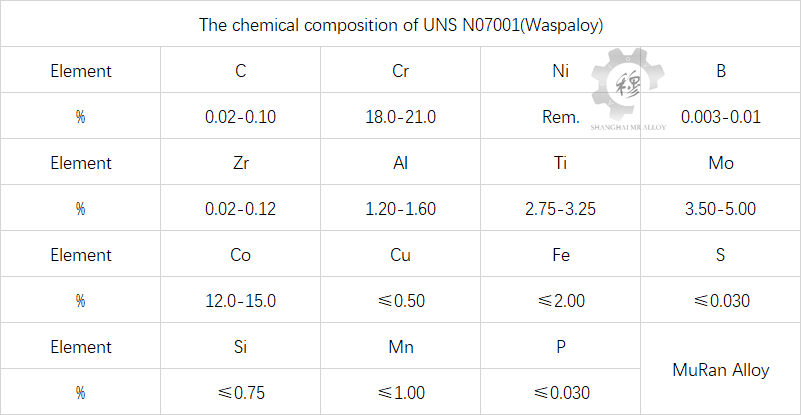

The chemical composition of UNS N07001(Waspaloy)

Tech Center 2025-07-29 149

Waspaloy(UNS N07001/W. NR.2.4654) is a nickel-based, age-hardening superalloy with excellent high-temperature strength and good corrosion resistance, especially at a service temperature of 1200°F(650 ° C), for critical rotational applications. And other less demanding applications up to 1600°F(870 ° C). The high-temperature strength of this alloy comes from its solid solution strengthening elements molybdenum, cobalt and chromium, as well as its aging hardening elements aluminum and titanium. Its strength and stability range are higher than those of the commonly available 718 alloy.

Special metal Waspaloy is used in gas turbine engine components, which need to have considerable strength and corrosion resistance at high temperatures. Current and potential applications include compressor blades and rotor discs, shafts, gaskets, seals, rings and housings, fasteners, and various other engine hardware, frame assemblies, and missile systems.

This alloy exhibits excellent oxidation resistance under frequent thermal cycling conditions and performs well when continuously exposed to temperatures up to 1900°F(1038 ° C). This alloy performs well in the atmosphere and salt spray environment found in gas turbine engine services. Solution treatment materials offer the best level of corrosion resistance.

The density of this alloy is ρ=8.19g/cm³.