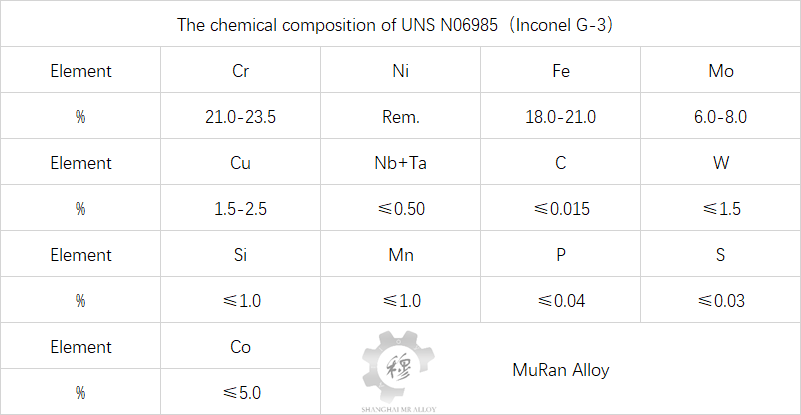

The chemical composition of UNS N06985(Inconel G-3)

Tech Center 2025-08-01 142

Inconel G-3 is a nickel-chromium-iron alloy with molybdenum and copper added. The control of some minor elements can enhance the resistance to heat-affected zone (HAZ) corrosion and improve the welding performance. Alloy G-3 has excellent corrosion resistance to oxidizing chemicals and atmospheres. Due to its nickel and copper content, it is also resistant to reducing chemicals. Nickel also endows the alloy with excellent resistance to stress corrosion cracking in chlorine-containing environments. High molybdenum provides excellent resistance to pitting and crevice corrosion. Low carbon helps prevent sensitization and endows alloys with the ability to resist intergranular corrosion.

Inconel G-3 is particularly suitable for treating reducing acids such as phosphoric acid and sulfuric acid. It is used in flue gas desulfurization systems (scrubbers), especially in quenchers, baffles and outlet pipe areas. It can be used in other air pollution control systems in the chemical and pulp and paper industries. It is a good candidate material for evaporators, heat exchangers, water tank linings and other equipment in phosphoric acid manufacturing plants. This alloy is widely used as an oil well pipe (OCTG) in hot and acidic environments.

The density of this alloy is ρ=8.14g/cm³.