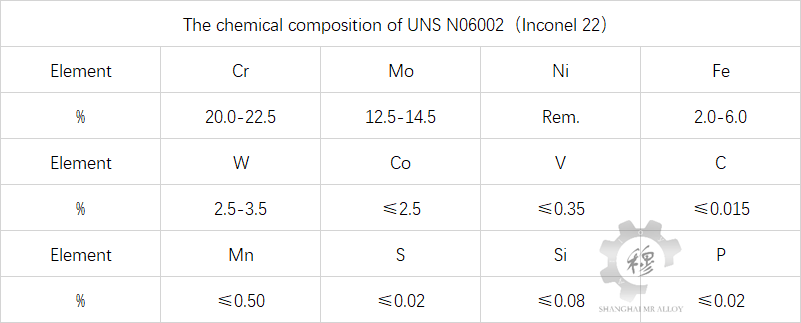

The chemical composition of UNS N06002(Inconel 22)

Tech Center 2025-07-30 130

Inconel 22 is a fully austenitic high-grade corrosion-resistant alloy, which is resistant to both water corrosion and high-temperature corrosion. This alloy has excellent resistance to general corrosion, pitting corrosion, crevice corrosion, intergranular corrosion and stress corrosion cracking. Inconel22 has extensive applications in industries such as chemical/petrochemical processing, pollution control (flue gas desulfurization), power, Marine, pulp and paper processing, and waste treatment.

Inconel 22 is a nickel-based alloy, typically containing 22% chromium, 14% molybdenum and 3% tungsten. The iron content is usually limited to below 3%. The high chromium content in the alloy endows it with excellent resistance to wet corrosion from oxidizing media such as nitric acid, iron salts and copper salts. The content of molybdenum and tungsten makes the alloy resistant to the corrosion of wet reducing media such as sulfuric acid and hydrochloric acid. Inconel 22 has excellent resistance to seawater corrosion under both static and flowing conditions.

At high temperatures, the high chromium content of Inconel 22 helps it resist oxidation, carburization and sulfidation. As it is a nickel-based alloy, Alloy 22 can resist the erosion of halides such as chlorides and fluorides at high temperatures. With these characteristics, this alloy is widely used to protect steel pipes and other components in coal-fired boilers and waste-to-energy boilers.

The density of this alloy is ρ=8.61g/cm³.