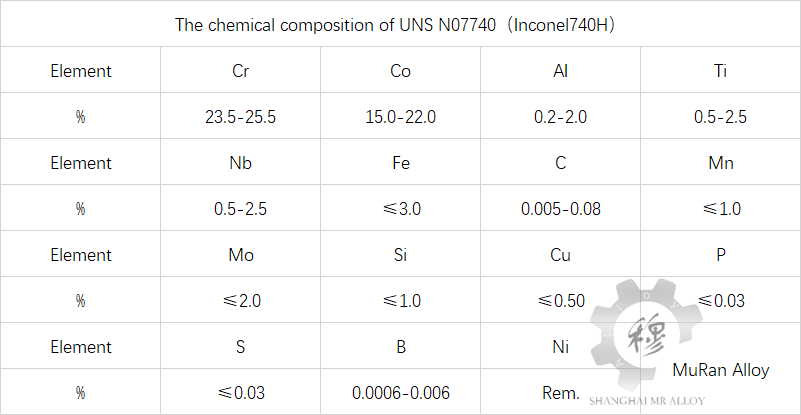

The chemical composition of UNS N07740(Inconel740H)

Tech Center 2025-07-30 284

Inconel 740H is a nickel-based precipitation-hardening superalloy that offers a unique combination of high strength and creep resistance at high temperatures, while also having resistance to coal ash corrosion. The initial target of this alloy was to be used as A-USC boiler tubes in the superheated sections of these factories, but it was later changed to be used as the material for the main steam tubes connecting the boiler tubes. A-USC boiler tubes are of traditional size [typically with an outer diameter of 1.5 to 3 inches (38 to 76 millimeters)]. The diameter range of the main steam pipe is much larger, with an outer diameter greater than 12 inches (305 millimeters) and a wall thickness that may exceed 1.5 inches (38 millimeters). Seamless steam reheating pipes with an outer diameter of up to 30 inches (760 mm) are also a viable product line for the Inconel740H.

Inconel740H(UNSN07740) is a derivative of nickel-chromium-titanium alloy 263. With its relatively high chromium content (24.5%), Inconel740H offers a significant improvement in high-temperature corrosion resistance mechanisms. Inconel740H ages and hardens due to the precipitation of (Y’). By balancing the hardener content (niobium, aluminum and titanium), Inconel740H not only exhibits high strength but also demonstrates excellent thermal stability.

The density of this alloy is ρ=8.05g/cm³.