Introduction of W.Nr.2.4819(Inconel C-276)

Tech Center 2025-08-30 193

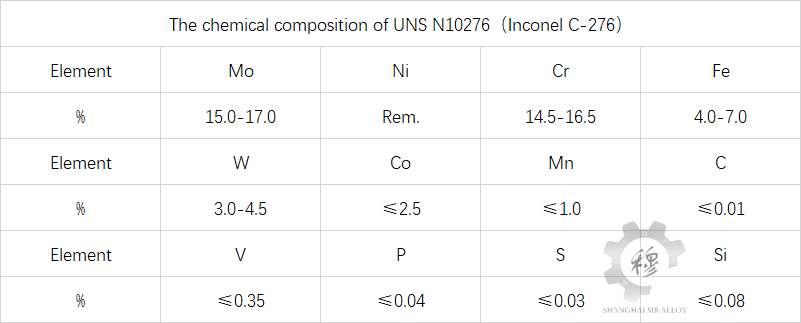

Overview of C276

C276 is an improved ultra-low carbon Ni-Mo-Cr series nickel-based corrosion-resistant alloy, which has excellent corrosion resistance and stress corrosion cracking resistance to various strong corrosive and chemical media. Currently, it is widely used in aviation, chemical industry, power plant desulfurization and other fields. Based on the excellent corrosion resistance of this material, China has selected C276 as one of the candidate materials for cladding.

The currently recognized representative candidate materials for SCWR cladding include ferritic/martensitic steel, austenitic stainless steel, nickel-based alloys and ODS. Nickel-based alloy C276 is a nickel-based alloy with a high content of Cr and Mo. Due to its excellent corrosion resistance, it has been widely used in the chemical industry and desulfurization equipment in thermal power plants, and thus its corrosion resistance has been extensively studied.

High-temperature creep performance of C276

1) The creep curve of C276 at 600℃ under various stresses exhibits the creep characteristics of the second type of solid solution. At 650 to 750℃ under low stress, it exhibits the creep characteristics of Type 1 solid solution, and at high stress, it shows the creep characteristics of Type 2.

2) The steady-state creep rate of C276 at a relatively low stress level of 600℃ and at 650-750 ℃ has a good linear relationship with the stress in the double logarithmic coordinate system, but deviates from this linear relationship at a high stress level of 600℃.

3) It is relatively reliable to predict the creep life of C276 at a relatively low stress level of 600℃ and 650℃ using the Monkman-Grant empirical formula. It is safer to apply the L-M parameter method at a high stress level of 600℃ and at 700 ℃ and 750℃.

4) C276 has better high-temperature creep performance than nickel-based alloys Incoloy 800 and Inconel 690.

Tensile mechanical properties of C276

Below 600 ℃, as the temperature rises, both the yield strength and fracture strength of nickel-based material C276 decrease. Above 600 ℃, its yield strength and fracture strength also decrease, but there is a peak strength around 600 ℃. From the perspective of real stress-strain, the fracture strength of nickel-based material C276 increases with the rise in temperature below 600 ℃. However, above 600 ℃, its fracture strength decreases, and there is a peak strength near 600 ℃. Analysis shows that the fracture strength under real stress and strain is much higher than that under nominal stress and strain.

Corrosion resistance of C276

(1) C276 alloy mainly undergoes uniform corrosion in supercritical water at 550 ~ 650 ℃ /25 MPa, and its corrosion weight gain follows a parabolic growth law.

(2) When the temperature rises from 550 ℃ to 600 ℃, the corrosion weight gain of C276 alloy approximately increases by three times, while when the temperature further rises to 650 ℃, its corrosion weight gain is only twice that at 550 ℃.

(3) The solubility of metal oxides in supercritical water is relatively low. The corrosion mechanism of C276 alloy in supercritical water belongs to solid-state growth, that is, metal ions within the base material diffuse outward and O2 – from the outside diffuses into the material, and oxidation reactions occur to form an oxide film covering the material surface.

(4) The delamination of the oxide film on the surface of C276 alloy is not obvious. The main components of the oxide film are (Ni, Fe) Cr2O4, and at the same time, a large amount of NiO oxide particles are discretely distributed on its surface layer. The protective performance of the oxide film mainly depends on the Cr content within it. The higher the Cr content, the denser its structure, which can better inhibit the diffusion of metal ions and O2 -.

The above is an introduction of the material and properties of C276 Hastelloy nickel-based alloy. Our company’s official website (wellalloy.com) updates relevant alloy information. Welcome to visit and exchange.