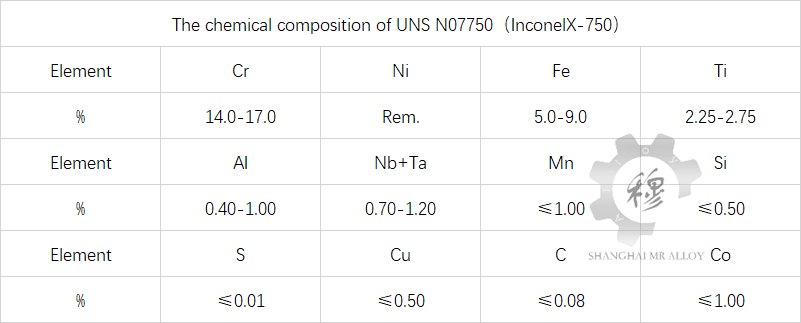

Introduction of UNS N07750(InconelX-750)

Tech Center 2025-08-28 510

Inconel X-750 is a precipitation-hardening nickel-chromium alloy that is used for its corrosion resistance, oxidation resistance and high strength up to 1300°F. Although the effect of precipitation hardening will be greatly reduced when the temperature exceeds 1300°F, the heat-treated material still has useful strength at 1800°F. The Inconel X-750 also has excellent performance at extremely low temperatures.

In gas turbines, Inconel X-750 is used for rotor blades and discs, bolts and other structural components. Inconel X-750 is widely used in the thrust chambers of rocket engines. Rack applications include thrust reversers and hot air duct systems. Large pressure vessels are made of Inconel X-750. Other applications include heat treatment fixtures, forming tools, extrusion dies and test machine fixtures. For springs and fasteners, the Inconel X-750 is used from minus to 1200°F.

Heat treatment of Inconel X-750:

According to the application and the required characteristics, various heat treatment methods are adopted:

In applications above 1100°F, especially when loads need to be endured for long periods of time, the best performance can be achieved through annealing treatment (2100°F) followed by stabilization treatment (1550°F) and precipitation treatment (1300°F). In applications below 1100°F, alloys can be strengthened through precipitation treatment after hot or cold working, or precipitation treatment after balancing or annealing. Furnace cooling treatment is also used to develop the best performance for certain applications.

The density of this alloy is ρ=8.28g/cm³.