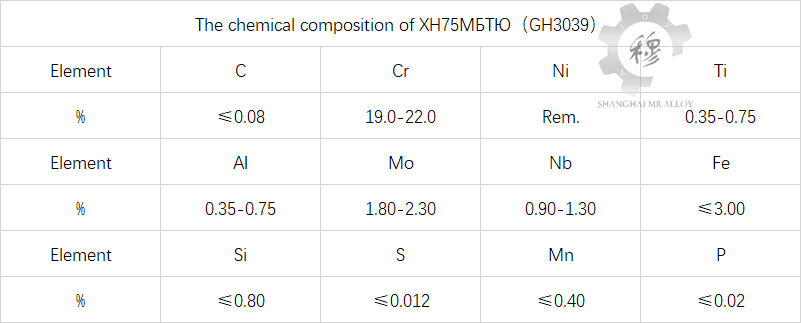

Introduction of XH75МБTЮ(RUS)GH3039

Tech Center 2025-08-11 157

XH75 MBTЮ(RUS)GH3039 overview:

XH75 MBTЮ(RUS)GH3039 is a single-phase austenitic solid solution strengthening alloy. It has moderate thermal strength and good thermal fatigue performance below 800℃, and good oxidation resistance below 1000℃. It has a stable structure after long-term use and also features excellent cold formability and welding performance. Components suitable for long-term use in the combustion chamber and afterburner of aero engines at temperatures below 850℃. This alloy can be used to produce plates, bars, wires, tubes and forgings.

XH75 MBTЮ(RUS)GH3039 Laser shock study:

High-temperature alloy XH75 MBTЮ(RUS)GH3039, as a solid-solution strengthened nickel-based alloy, features high-temperature resistance, corrosion resistance and excellent formability, and is often used to manufacture hot-end parts for aero engines. Due to the fact that the components of aero engines often operate in high-temperature and high-pressure environments and are subject to alternating loads, especially when the thrust-to-weight ratio is constantly increasing, enhancing the reliability of key components of aero engines and extending their service life holds significant social and military value.

Taking XH75 MBTЮ(RUS)GH3039 superalloy as the research object, the surface modification treatment was carried out by laser shock treatment technology. Research has found that laser shock treatment increases both the microhardness and surface roughness of the alloy’s surface layer, significantly changes the residual stress state within the metal, and enhances the surface integrity of the alloy. Compared with the base material, the grains of the laser shock specimen are significantly refined, but with the increase of shock times, the degree of grain refinement of XH75 MBTЮ(RUS)GH3039 weakens. No new phase or phase transition occurred in XH75 MBTЮ(RUS)GH3039 under different laser shock cycles. With the increase in the number of impacts, the intensity of the diffraction peak decreases, while the full width of the half peak significantly increases. This is attributed to the refinement of grains and the increase in microscopic strain.

That’s all about the nickel-based superalloy XH75 MBTЮ(RUS)GH3039. We welcome relevant practitioners to discuss with the editor together.

We will update relevant alloy information on our company’s official website (wellalloy.com) .